Process overview

1. Parts Preparation

| ID | 1.1. | |

| Title | Top Cover Preparation | |

| Scope | Prepare the top cover with adhesive tape for assembly | |

| Buy | Shop link for Top Covers |

Materials

- Top cover

- Kapton tape, 80 um, double sided silicon adhesive

Step-by-step

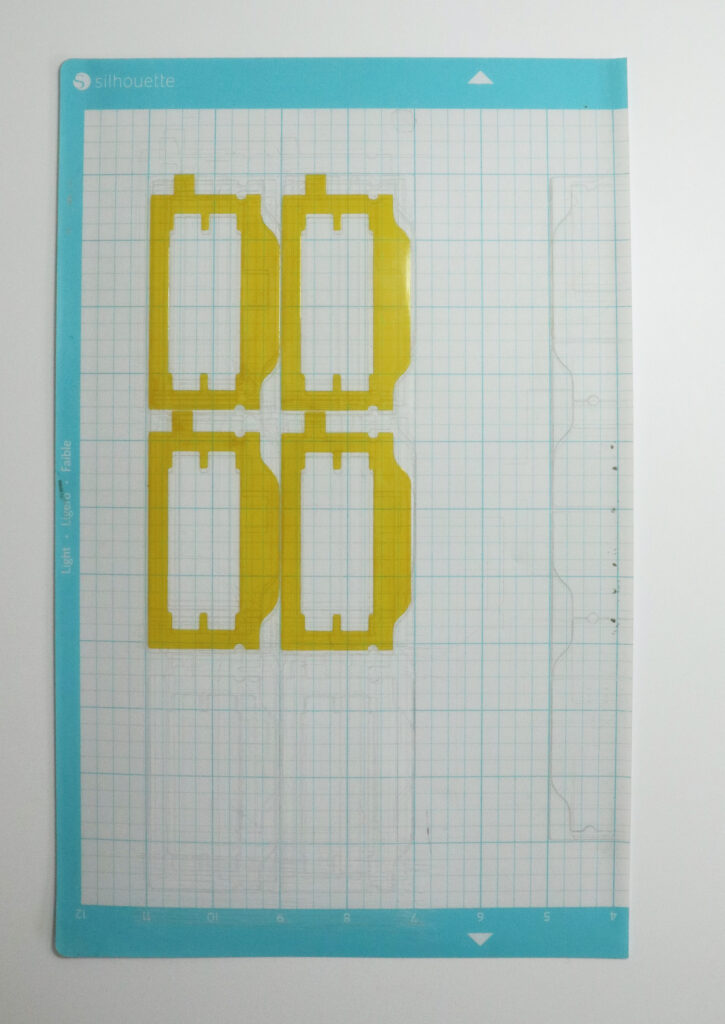

- Remove liner from double sided kapton tape and apply it to a non sticking cutting mat

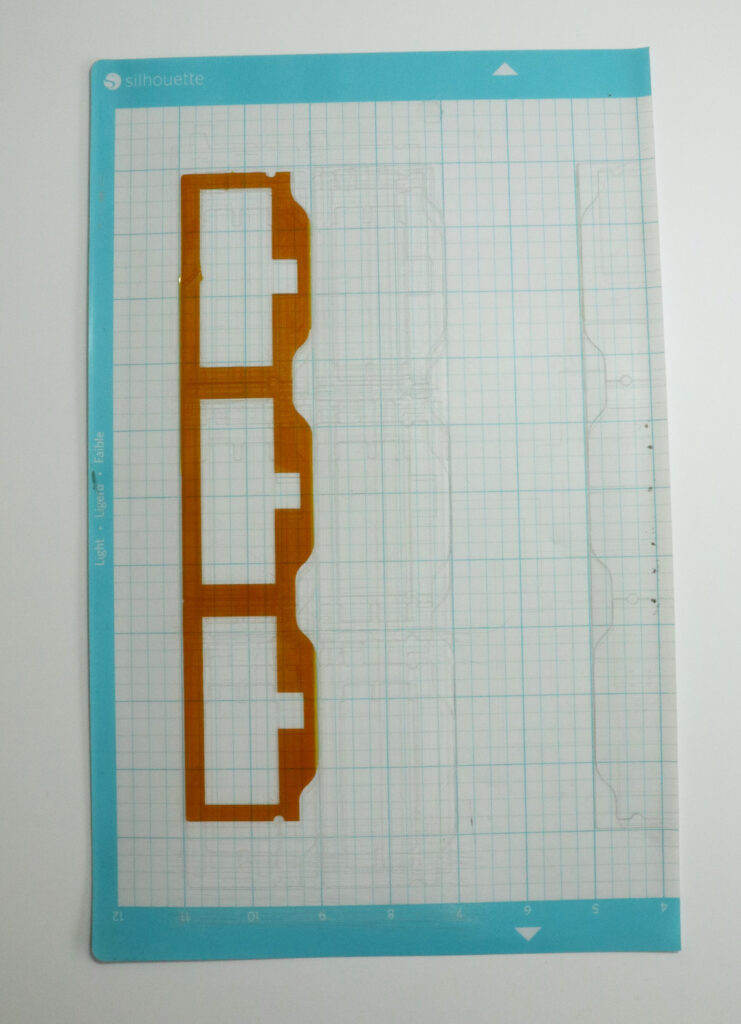

- Cut out kapton stickers using USB desktop cutter. File can be sent by smart phone app (fig 1)

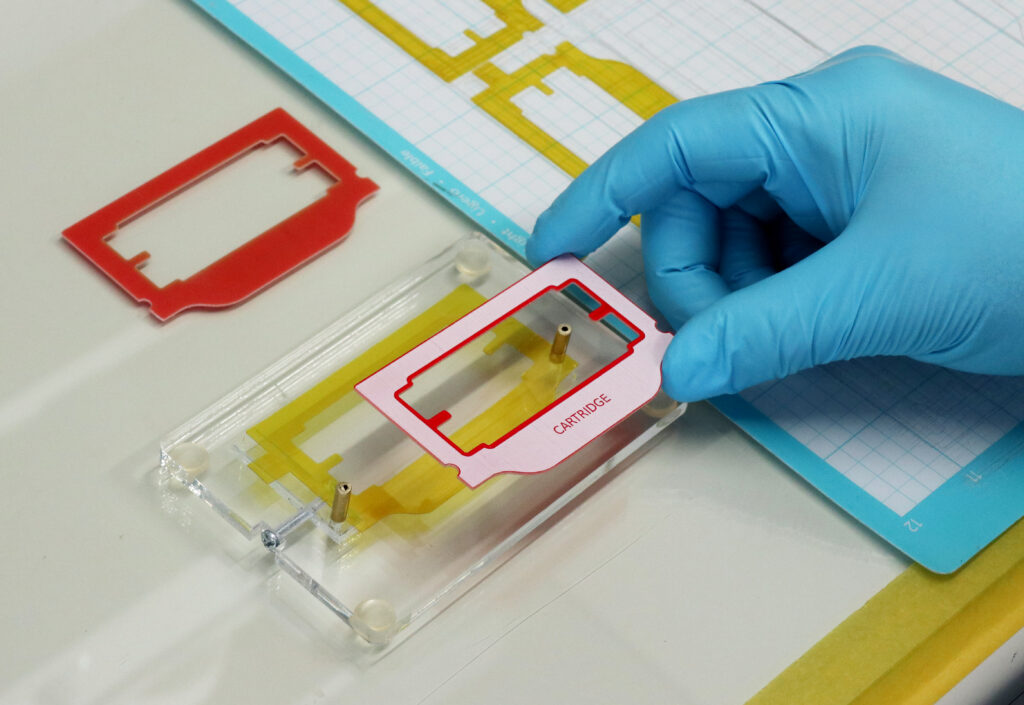

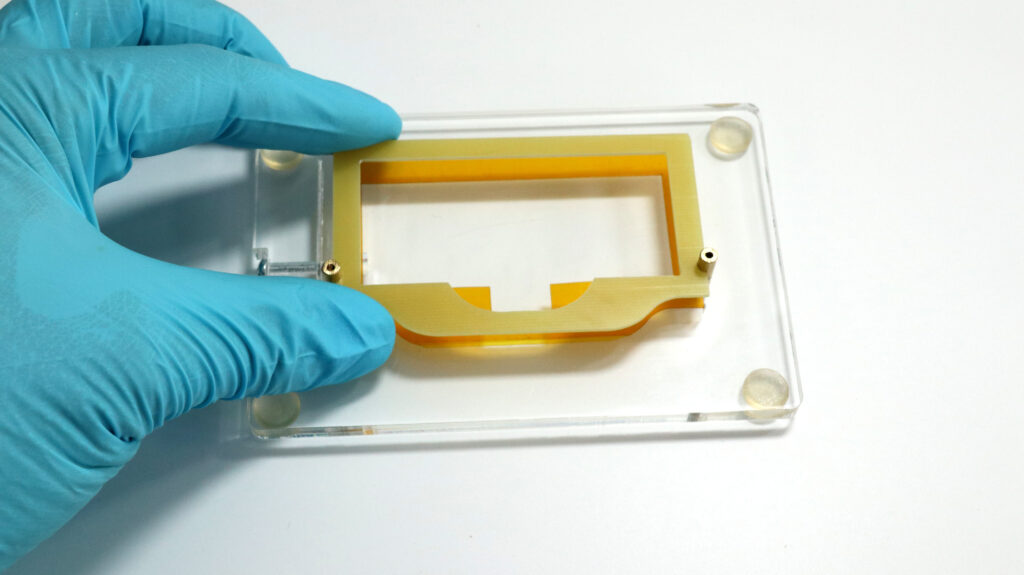

- Apply kapton sticker to top cover using the cartridge alignment jig. First lay down the sticker with the sticky side up then the cover. (fig 2)

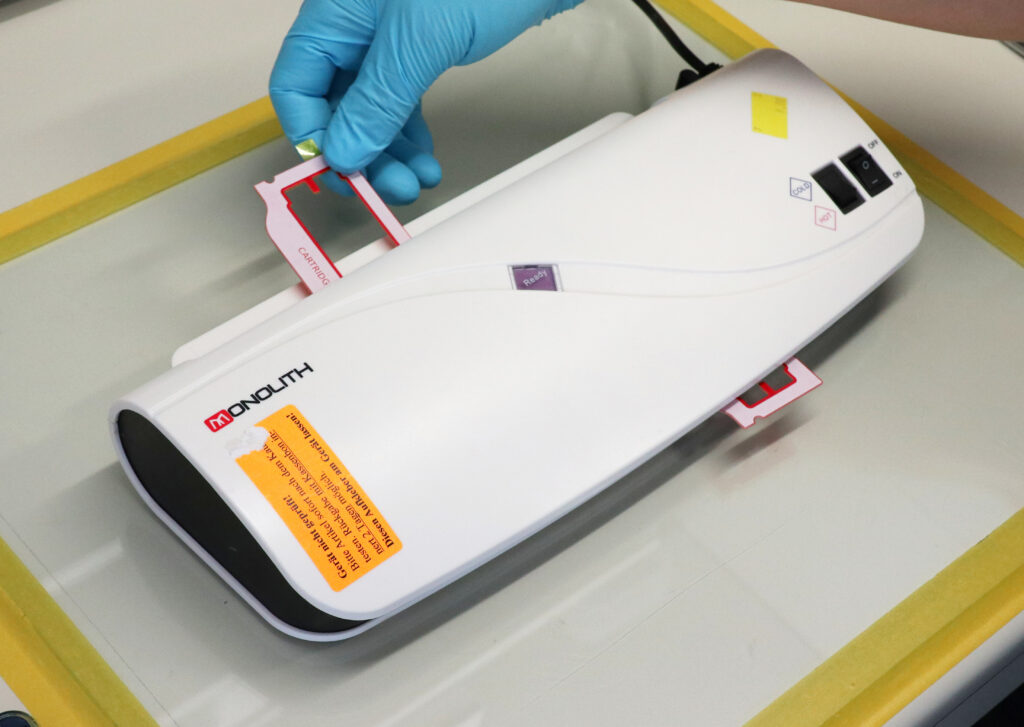

- Pass the top cover through a laminator (fig 3)

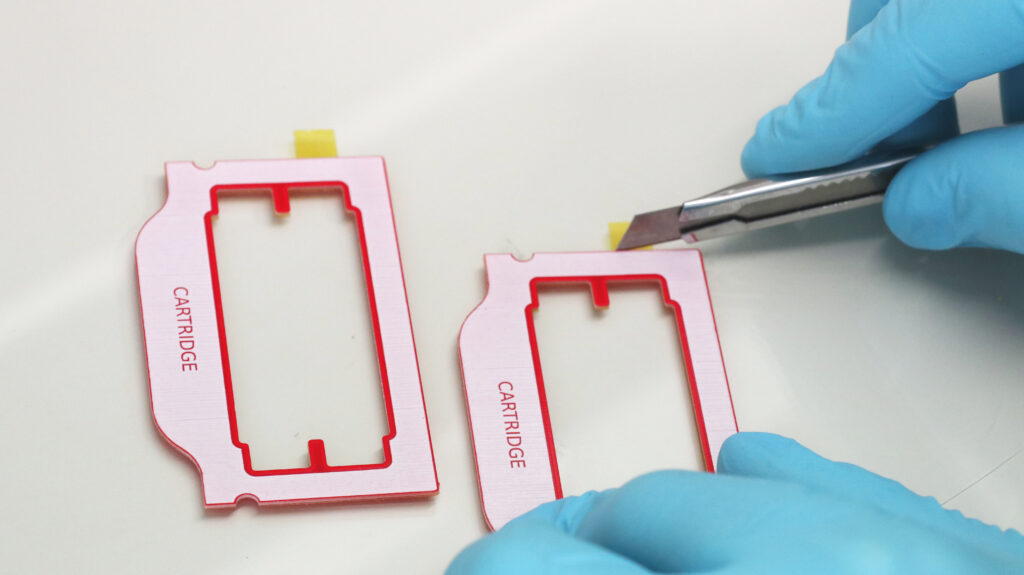

- Score the peel-off tap with a sharp knife close to the edge of the cover (fig 4)

- Remove the kapton from the peel-off tab (fig 5)

Pictures / Videos

fig 1

fig 2

fig 3

fid 4

Files / Templates:

| ID | 1.2. | |

| Title | Spacer Frame Preparation | |

| Scope | Prepare the space frame with adhesive tape for assembly | |

| Buy | Shop link for Spacer Frames |

Materials

- Spacer frame

- 278um 3M PET Membrane Switch Spacer with double sided acrylic adhesive (7961MP)

Step-by-step

- Cut out spacer using laser cutter. (fig 1)

- Apply spacer sticker to spacer frame using the cartridge alignment jig. First lay down the sticker with the sticky side up then the frame. (fig 2)

- Pass through the laminator

Pictures / Videos

fig 1

fig 2

Files / Templates:

| ID | 1.3. | |

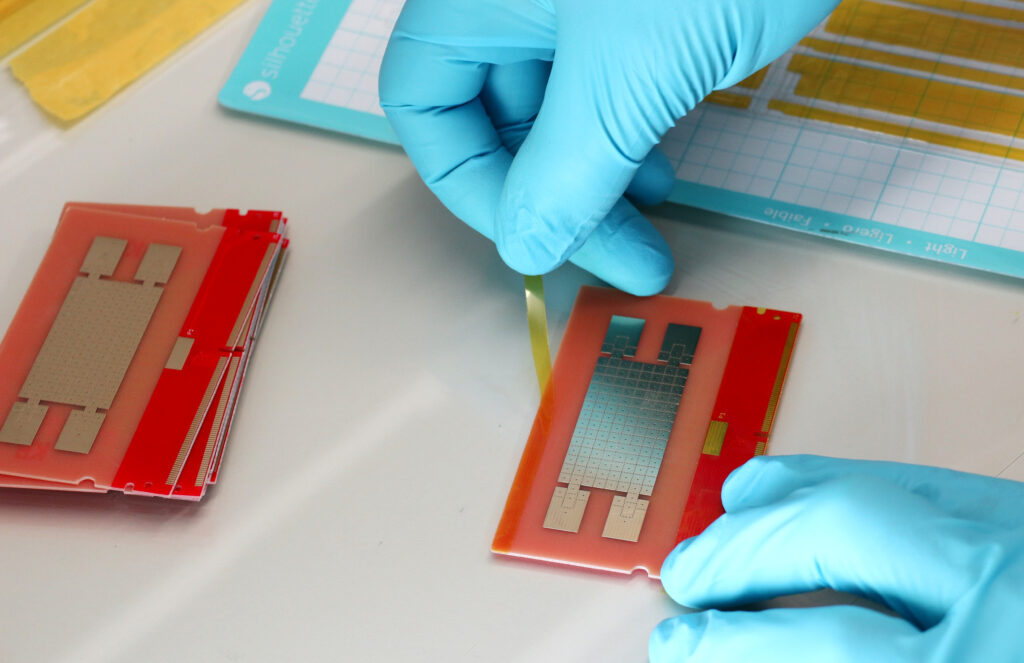

| Title | Electrode Board Preparation | |

| Scope | Prepare the electrode board with double sided adhesive masking for laminating | |

Materials

- Electrode baoard (shop link)

- Kapton tape, 80 um, double sided silicon adhesive

Step-by-step

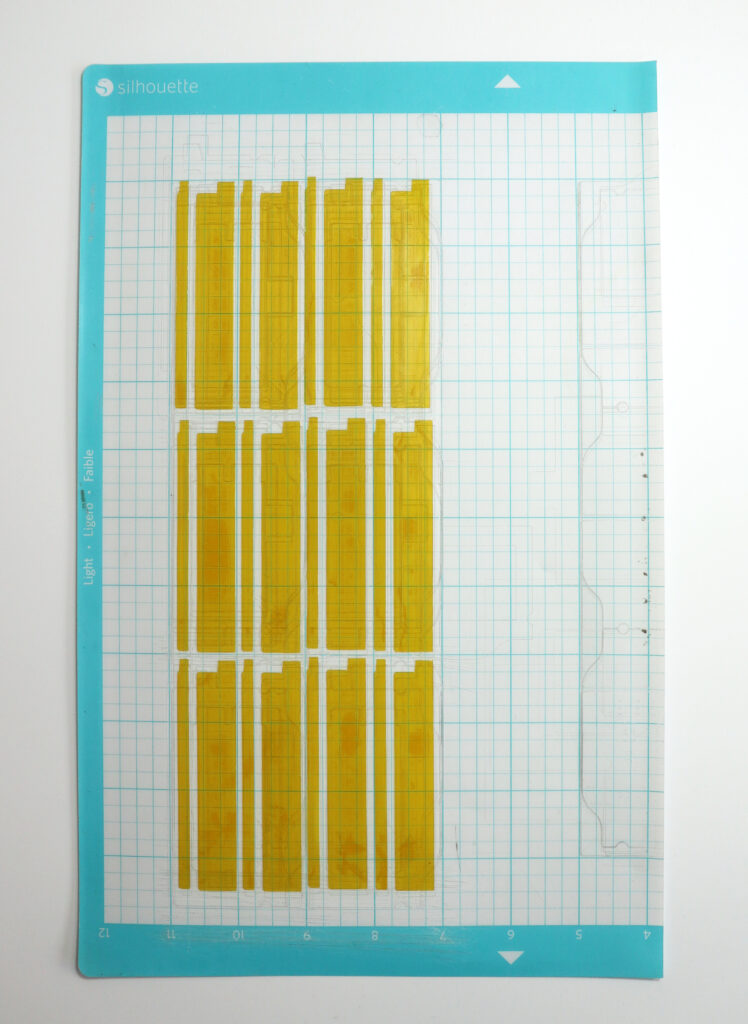

- Remove liner from double sided kapton tape and apply it to a non sticking cutting mat

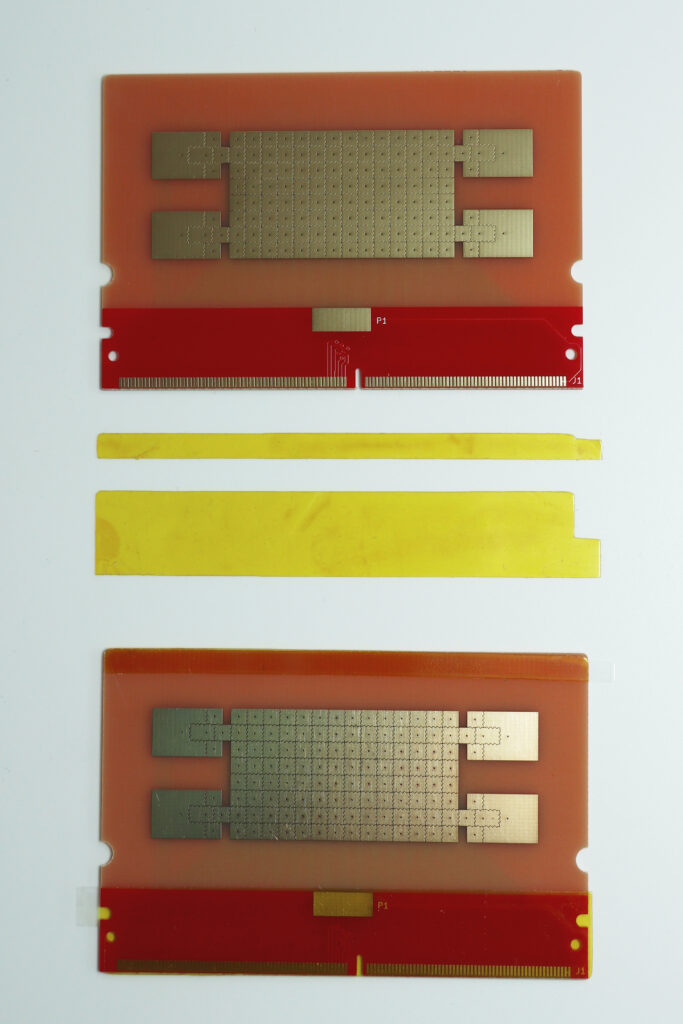

- Cut out kapton stickers using USB desktop cutter. File can be sent by smart phone app (fig 1)

- Apply kapton sticker to electrode board by aligning it as shown in fig. 2

- Pass electrode board through a laminator

Pictures / Videos

fig 1

fig 2

Files / Templates:

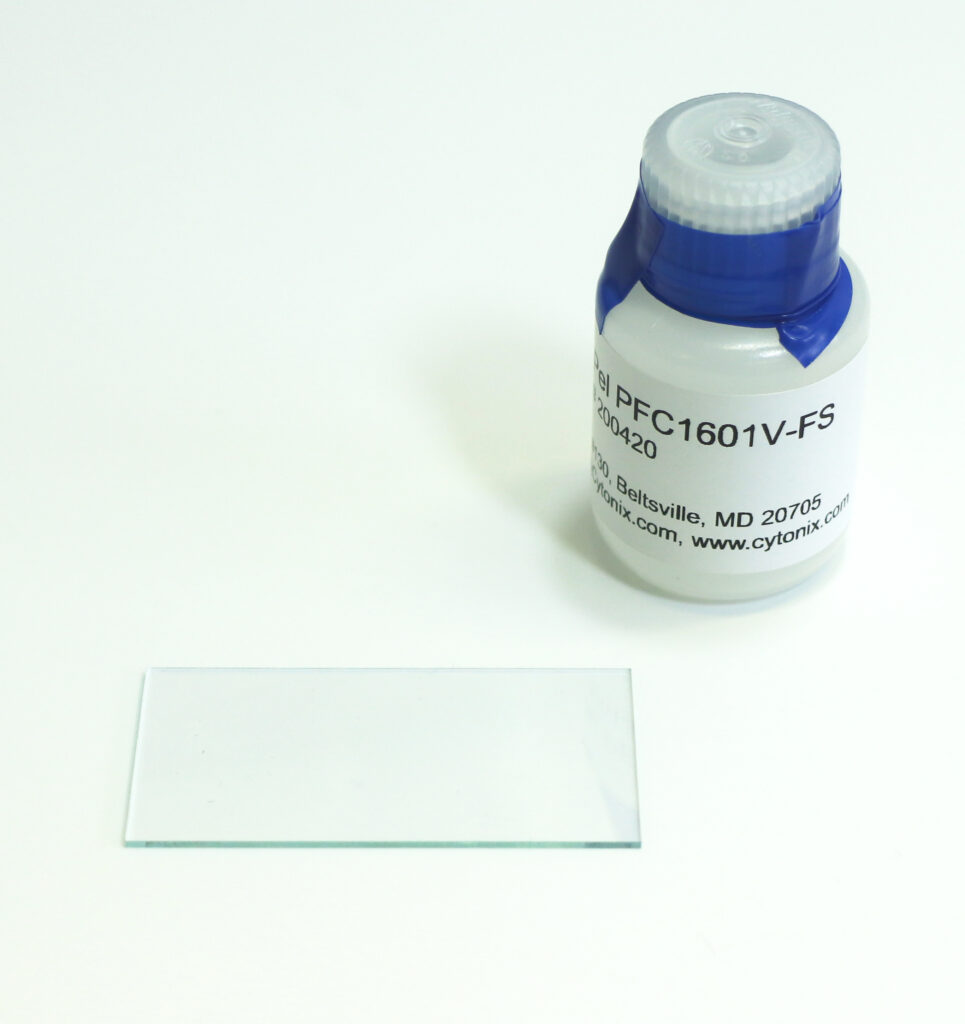

| ID | 1.4. | |

| Title | ITO Glass Coating | |

| Scope | Hydrophobic Coating of the ITO top cover glass | |

| Buy | Shop link for Hydrophobic Coated ITO glass |

Materials

- Conductive (ITO coated) top cover glass (shop link)

- Cytonix, Fluoropel coating – PFC1601V-FS

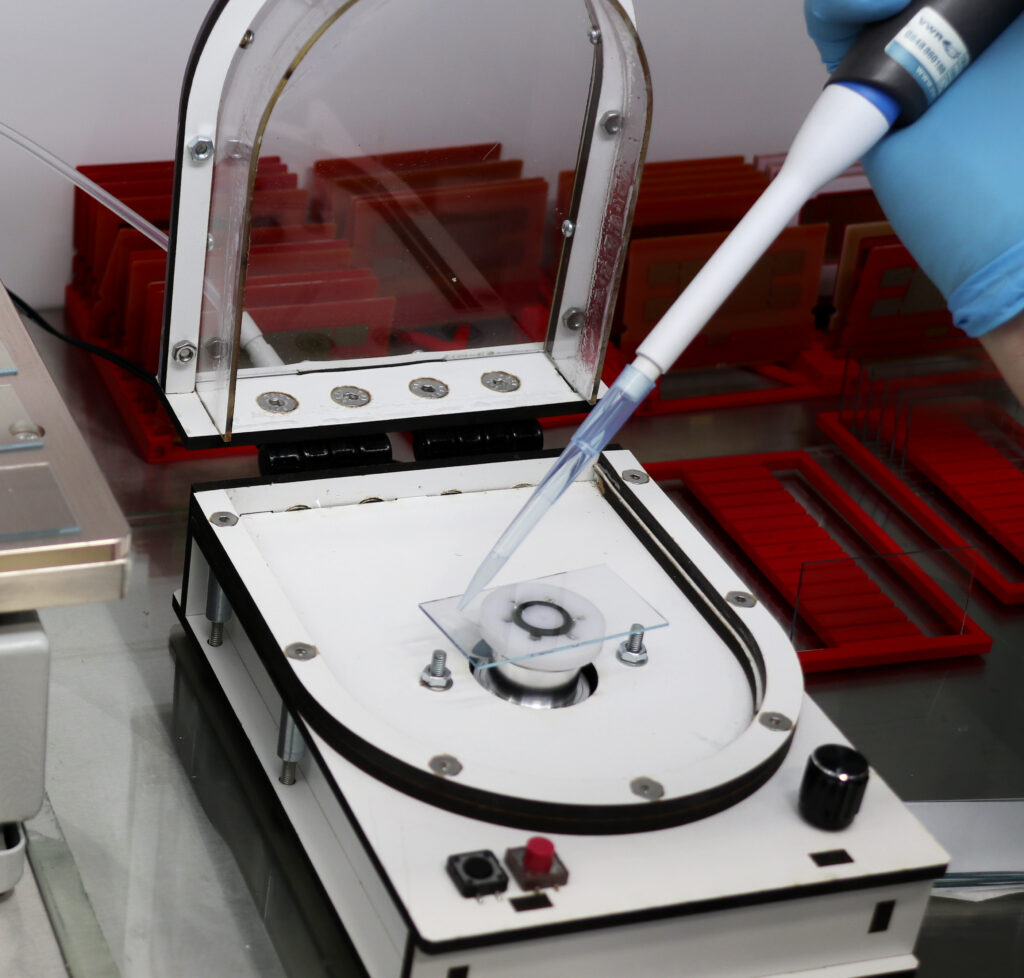

Step-by-step

- Using a multimeter test for the conductive side. (fig 1)

- Put the glass with the conductive side facing up on a spin-coater (with vacuum chuck)

- Apply 60 ul of Fluoropel coating using a micro pipette (fig 2)

- Spread the Fluoropel using a plastic squeegee over the full size of the slide (fig 3).

- Spin slide at 2500 rpm for 30 seconds

- Cure on hotplate at 180°C for 20 minutes (fig 4)

Pictures / Videos

fig 1

fig 2

fig 3

fig 4

Files / Templates: