Key to using the electro-wetting effect for moving droplets is a super hydrophobic and well gliding surface. There are different coating materials on the market for electro-wetting such as Fluoropel, Teflon AF or Cytop. These are amorphousfluoropolymer that can be deposited by spin coating or by dipcoating. For the first experiments with the OpenDrop we just used Polyethylen (PE) kitchen foil (saran wrap) coated with Rain-X a commercially available rain repellent for wind shields. Later we found parafilm and silicon oil to be a better combination for simple (topless) experiments. Most videos we shared are made with this combination. Later we developed more advanced solutions for devices with top cover using PTFE foil and Fluoropel. Also see our notes here for different materials that were tested.

*** Please be aware that electro-wetting on dielectric is a quite delicate process with many parameters that need to be controlled. You may need some experimenting and patience to get it to work. Also getting some background information on how the process works will help. ***

Electro-wetting in “topless configuration” using readily available materials, parafilm and silicon

For first experiments the so called “topless configuration”, without a cover glass is recommended. In this configuration the droplets just move on the surface without a glass cover on top as can be seen in this video.

What you need:

– Parafilm as used in most biolabs to seal stuff.

– Think, high viscous silicon oil. We use this standard ELBESIL SILIKONÖL B 5 oil with visicosity of 5 cSt. Any silicon oil with that viscosity should work. Note: regular kitchen oil has a viscosity of about 50-100 cSt and wont work well.

That’s how you do it:

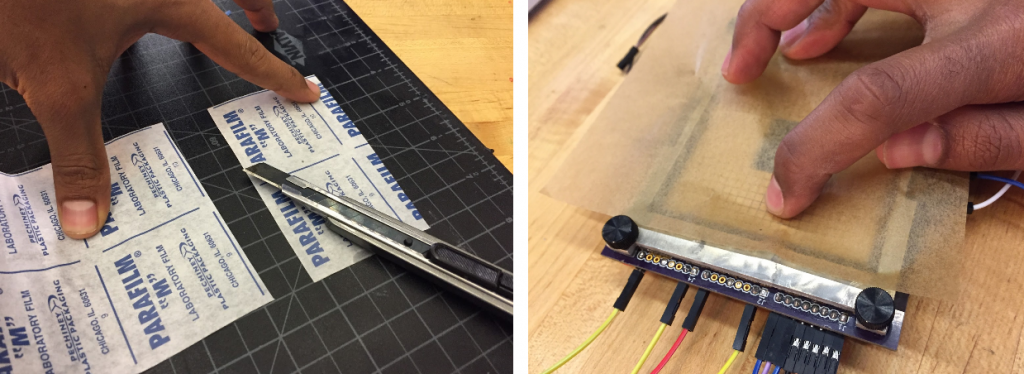

– Stretch a piece of parafilm in both directions to make it thin. It can help to attach it to a table with some scotch tape. Be sure to not stretch it to the point where you get holes in the foil. And also avoid wrinkles.

– Next apply a thin film of silicon oil on the electrodes to avoid air. Be careful to uses as little oil as possible as this will add to the dielectric gap

– Now cut out a piece of the streched parafil and apply it on the surface with the electrodes. With the OpenDrop you can use the foil carriere to do so.

– Add a thin layer of oil on top of the parafilm. You can use your finger (with gloves) to do so

– You can now put a droplet of water on the device. The size of the droplet should just cover about one electrode.

– To remove any static charge from the droplet, touching it with a grounded wire (that goes to GND).

– Test: The droplet should have a contact angle of more than 45° and when you tilt the device slightly the droplet should move easily on the surface and not stick.

– Turn on the high voltage and try to move the droplet.

Dual Layer Electro-wetting on hydrophobic foil

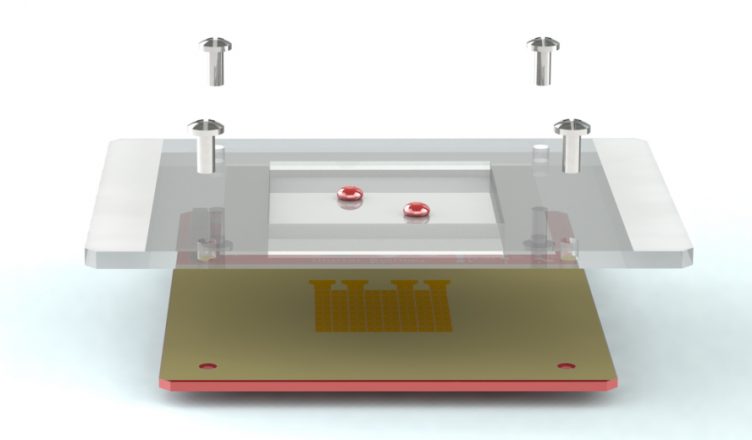

For more advanced experiments including feedback, smaller volumes, droplet splitting, as in this video, you want to use the so called “Dual Layer Electro-wetting”. A configuration with a conductive glass on top of the liquid droplets. For these experiments we used ETFE Foils coated with fluoropolymer.

Detailed process on how to do a hydrophobic coating using FluoroPel PFC1601V from Cytonix and ETFE Foils from Nowofol :